Montreal, Quebec — Beauce Gold Fields (Champs D’Or en Beauce) (TSXV: ¨BGF¨), (“BGF”): (“BGF” or the “Company”), referred to as “BGF” or the “Company,” is pleased to announce the trial results of a modified horizontal directional drilling (HDD) method to drill lengths of the auriferous till units of the paleoplacer channel on the Beauce Gold property located in Saint-Simon-les-Mine, Quebec.

Patrick Levasseur, President and CEO of Beauce Gold Fields, stated: “HDD drilling has demonstrated to be an efficient future method to support or possibly expand upon the Gold Exploration Target for the entire historical placer channel of our Beauce Gold property, which ranges between 61,000 ounces (2,200,000 m3 @ 0.87g Au/m3) and 366,000 ounces* (2,200,000 m3 @ 5.22 g Au/m3).” *Beauce Gold Fields 43-101 Report – Beauce July 4th 2018, Author B. Violette.

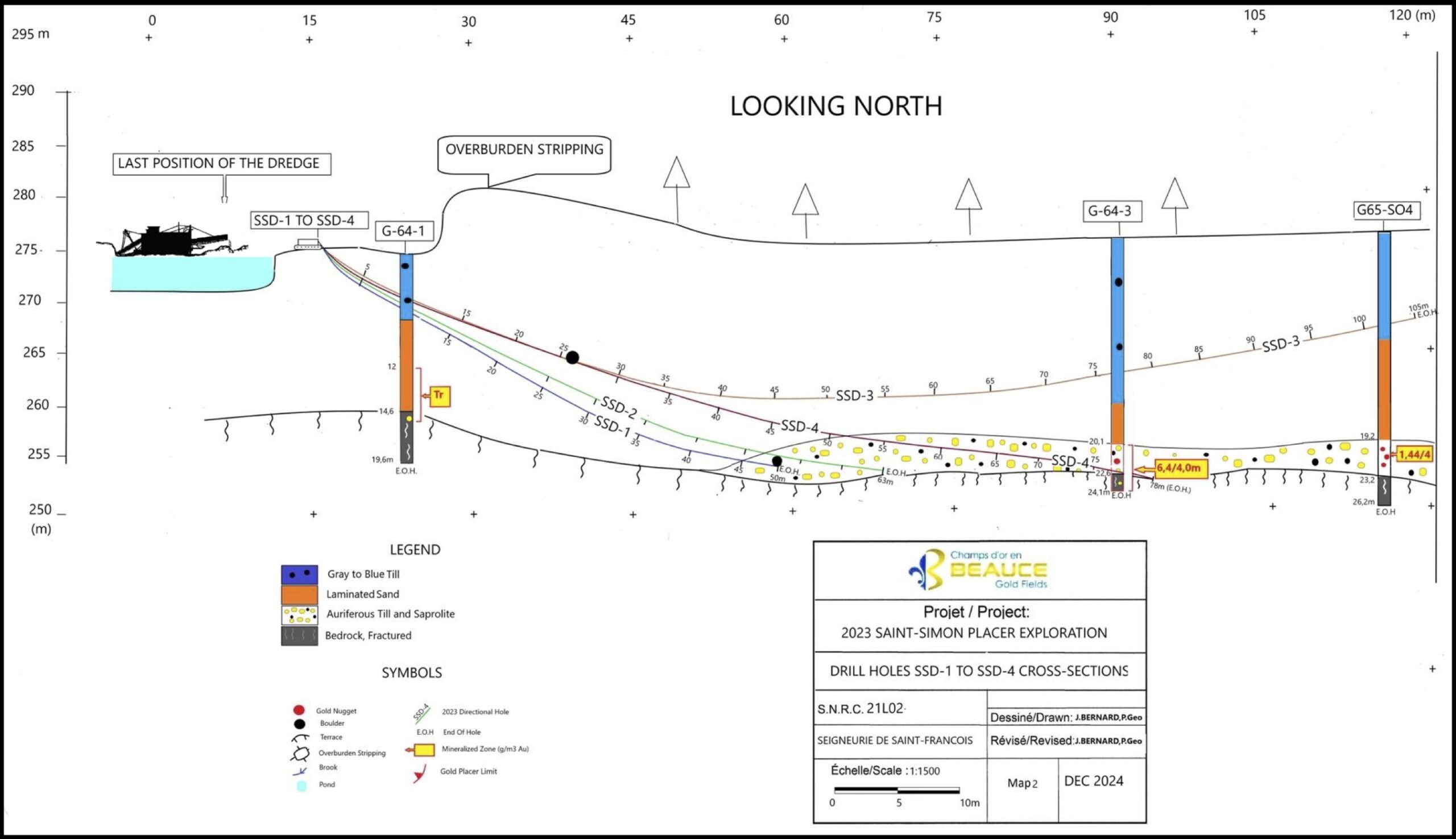

Image: Cross section of horizontal directional and overburden drill holes

In the summer of 2023 (see press release August 8, 2023), the Company tested the use of Horizontal Directional Drilling (HDD) as a possible low-cost and efficient method of sampling long lengths of placer deposits. From one location, four fanned-out HDD boreholes were completed, totaling 321 meters in overburden and intersecting portions of the auriferous till (Basal Till) and saprolite layers.

Placer exploration commonly uses vertical overburden drill holes with reverse circulation or sonic drilling. These methods provide shorter-length samples but yield more accurate grades of placer layers. However, they are costlier due to the proportionally longer lengths of sterile overburden that must be drilled through. HDD, on the other hand, is commonly used in construction and civil engineering projects. The technique is utilized to install utility lines (such as pipelines, fiber optic cables, and electrical conduits) without extensive excavation or disruption to existing infrastructure. Transmitters and a steering mechanism allows operators to adjust the direction of the drill path.

The Company experimented with this technique by combining an HDD rig and a vacuum tanker truck to collect a mix of bentonite mud and drill cuttings. Bentonite, commonly used in HDD, consists chiefly of crystalline clay minerals that help stabilize borehole walls, preventing collapse. As drilling progresses, the bentonite-based mud carries drill cuttings (rock fragments, auriferous till, and saprolite) back to the surface, which are then vacuumed into a tanker truck. The high viscosity of bentonite keeps cuttings suspended in the fluid, ensuring efficient removal from the borehole.

The bentonite mud and cuttings bulk material were emptied into geotechnical-lined pits for decanting. A mobile placer plant on-site processed the bulk samples to concentrate the material.

From one location, four fanned-out HDD boreholes were completed, totaling 321 meters in overburden and intersecting portions of the auriferous till (Basal Till) and saprolite layers.

Drill Hole Summary

|

Hole |

Horizontal Length |

Direction |

Aprox. Volume |

Comment |

|

Azimuth |

Bentonite & Cut. |

|||

|

SSD-1 |

50 meters |

N105 |

3.5 m3 |

Stopped by boulder at 50 meters |

|

SSD-2 |

63 meters |

N130 |

1.0 m3 |

Traverses 15m of saprolite |

|

SSD-3 |

135 meters |

N050 |

8 m3 |

Off-course, deviated by boulder at 26m |

|

SSD-4 |

78 meters |

N095 |

5 m3 |

Tests 38m lateral width of placer layers |

Only drill hole SSD-4 had sufficient bulk material to process. HDD drill hole SSD-4 drilled 78 meters and successfully bored horizontally through 38 meters of auriferous till and saprolite. From the 78 meters, a consolidated mix of 5m3 of bentonite mud and cuttings material, comprising both sterile overburden and auriferous till and saprolite, was collected. This was reduced to 24 kilograms of concentrate. Visible gold and pyrite were observed in the concentrate.

In the fall of 2024, six random samples of the concentrate, ranging from 140 grams to 260 grams, were sent to MSALABS in Val d’Or, Quebec, for fire assay analysis. A 250-gram sample returned 2.75 g/m3 of gold (1.1 g/t). The other five samples returned no gold values (MSALABS test certificate YVO2411283).

Observations for Future Use of HDD in Placer Gold Exploration

- Cost-effective to identify areas and potential extents of placer deposits.

- Allows for targeted follow-up exploration by vertical overburden drilling of specific areas of interest within the paleoplacer channel.

- Larger borehole diameters are needed to limit the drag-or effect (loss of nuggets into the borehole walls of bentonite due to centrifugal forces).

- Use of more robust drill head pilot bits to pierce through boulders.

Jean Bernard, BSc, Geo, a qualified independent person as defined by National Instrument 43-101, has reviewed and approved the technical information contained in this release. QA/QC procedures for the reported samples include the use of Certified Reference Materials from MSALABS (Test Certificate YVO 24011283). The FAS-425 analytical method was applied.

Beauce Gold Fields is a gold exploration company focused on placer to hard rock exploration in the Beauce region of Southern Quebec.