Montreal, Quebec — Beauce Gold Fields (Champs D’Or en Beauce) (TSXV: ¨BGF¨), (“BGF”): (“BGF” or the “Company”): is pleased to announce it has tested the use of a modified horizontal directional drilling method to drill lengths of the auriferous till units of the paleoplacer channel on the Beauce Gold property located in St-Simon les Mine, Quebec.

“Horizontal directional drilling has the potential to revolutionize placer gold exploration,” said Patrick Levasseur, President, and CEO of Beauce Gold Fields. Mr. Levasseur also emphasized, “If successful, this innovative technique will not only enhance cost-efficiency but also significantly improve sample coverage and reduce environmental impact, marking a significant leap forward in our exploration efforts.”

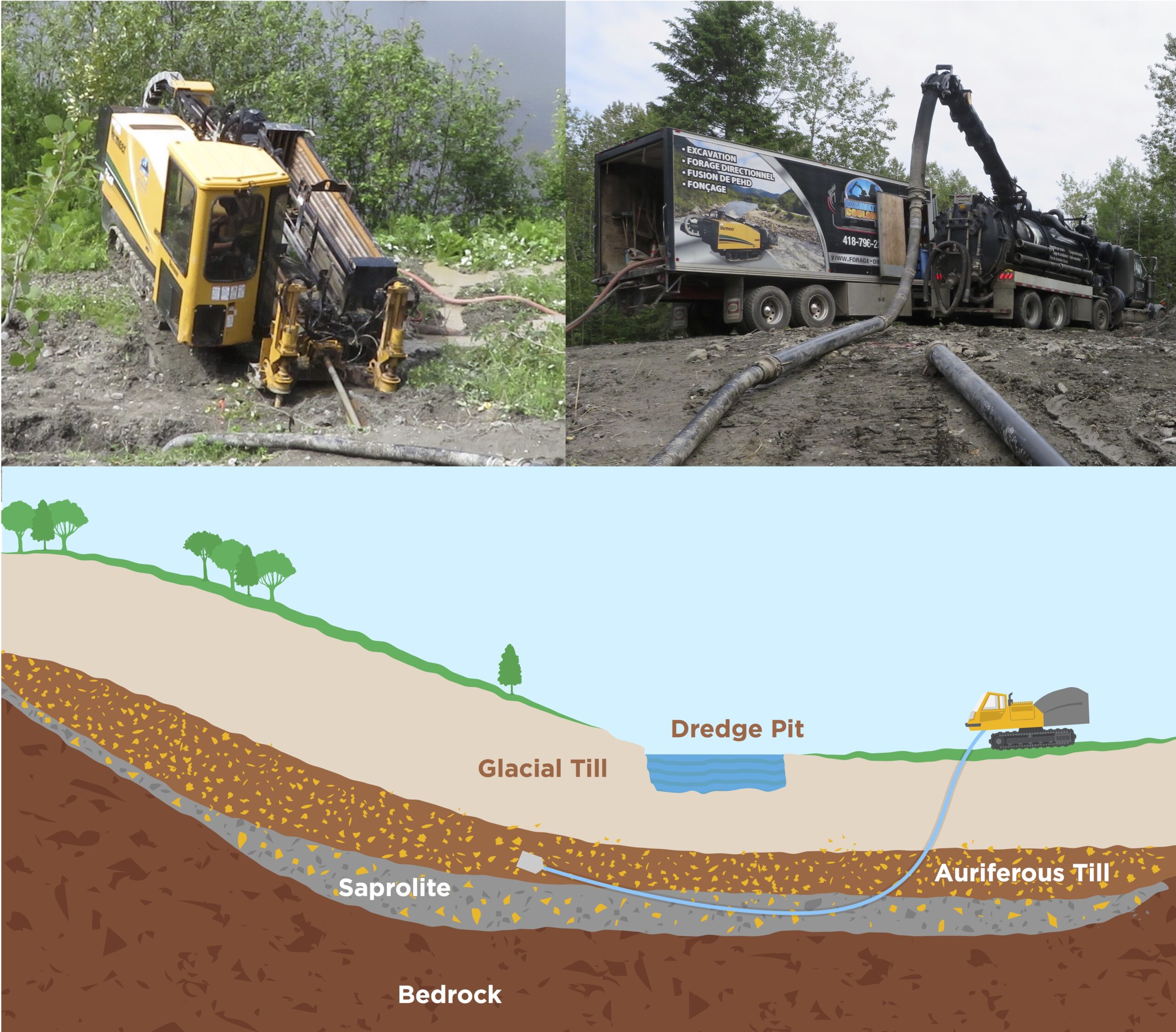

Image: from top left: Horizontal Directional Drill; Vacuum Tanker Truck; Diagram

Horizontal directional drilling (HDD) is commonly used in construction and civil engineering projects. The technique is utilized to install or replace utility lines (such as pipelines, fibre optic cables, electrical conduits, etc.) without extensive excavation or disruption to existing infrastructure. The Company recently experimented with the technique by combining an HDD rig and a vacuum tanker truck to collect the mix of bentonite mud and drill cuttings. Bentonite, commonly used in HDD, consists chiefly of crystalline clay minerals that help stabilize the borehole walls, preventing it from collapsing. As the drilling progresses, the bentonite-based mud carries the drill cuttings (rock fragments, auriferous till and saprolite) back to the surface, which is then vacuumed into a tanker truck. The high viscosity of bentonite helps to keep cuttings suspended in the fluid, ensuring efficient cuttings removal from the borehole.

The bentonite mud & cuttings material were emptied in geotech-lined pits for decanting. Various tests and trials will be performed on the material to see the best method of separating the bentonite to create heavy mineral concentrates that can be analyzed for gold. If the Company settles upon a successful separation method, a mobile placer plant will be mobilized on-site to process the material.

From one location, four fanned-out HDD boreholes were completed, totalling 321 meters in the auriferous till (Basal Till) and saprolite layers.

| Hole | Horizontal Length |

Direction Azimuth |

Aprox. Volume Bentonite & Cut. |

Comment |

| D-1 | 63 meters | N105 | 3.5 m3 | Target to hole G64-3, 3.4g/m3* Au |

| D-2 | 30 meters | N130 | 1.0 m3 | Hit boulder, hole abandoned at 30m |

| D-2.5 | 51 meters | N120 | 1.5 m3 | Test lateral width of placer channel |

| D-3 | 135 meters | N050 | 8 m3 | Target to hole G65-S04 1.44 g/m3* Au |

| D-4 | 72 meters | N095 | 5 m3 | Test lateral width of placer channel |

*Sources: Sedar- Beauce Gold Fields 43-101 Report – Beauce July 4th 2018, Author B. Violette.

Five Advantages of Horizontal directional drilling

If successful, using directional horizontal drilling to explore and drill the paleoplacer channel on the Companies placer gold properties will offer many advantages:

1. Enhanced Exploration: Directional horizontal drilling allows for targeted exploration of specific areas of interest within the paleoplacer channel. By drilling at angles or curves, geologists can access hard-to-reach or hidden gold-bearing zones that traditional vertical drilling might miss.

2. Increased Coverage: Directional drilling enables extensive coverage of the paleoplacer channel with fewer drill holes. This efficiency can significantly reduce drilling costs.

3. Improved Sampling: Horizontal drilling allows for better sampling along the length of the paleoplacer channel. This means more representative samples of the gold-bearing formation can be collected, leading to more accurate estimations of the gold resource.

4. Minimized Environmental Impact: By using directional drilling, the surface disturbance on the Beauce gold property can be minimized, reducing the project’s overall footprint and potential environmental impacts.

5. Resource Estimation: The data collected from directional horizontal drilling can be used to estimate the size, shape, and continuity of the gold deposit within the paleoplacer channel more precisely. This information is critical for determining the economic viability of the deposit and planning future mining operations.

Jean Bernard, B,Sc. Geo., is a qualified person, as defined by NI 43-101, who has reviewed and approved the technical information presented in this release.

Beauce Gold Fields is a gold exploration company focused on placer to hard rock exploration in the Beauce region of Southern Quebec.